Search Case Studies

End-Use Case Study

- Compounds Eliminate Fragile Surfactant Coatings

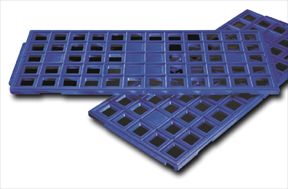

Traditionally, applications such as chip trays in glass-filled ABS or polystyrene are dip-coated to impart conductivity. These coatings easily wear or abrade away through contact with electronic components or general handling. They are also dependent on environmental moisture for optimum performance.

Static Dissipative Compounds are non-sloughing, perform independent of environmental moisture, and can be cleaned without losing static dissipative performance. They are colorable to assist with identification and are bakeable at 65 degrees C (149 degrees F) for 24 hours.

In addition to styrenic formulations, RTP Company has developed compounds in polypropylene and polyethylene for applications like cleanroom tool grips, totes and boxes for electronic component transport, and general ESD applications.