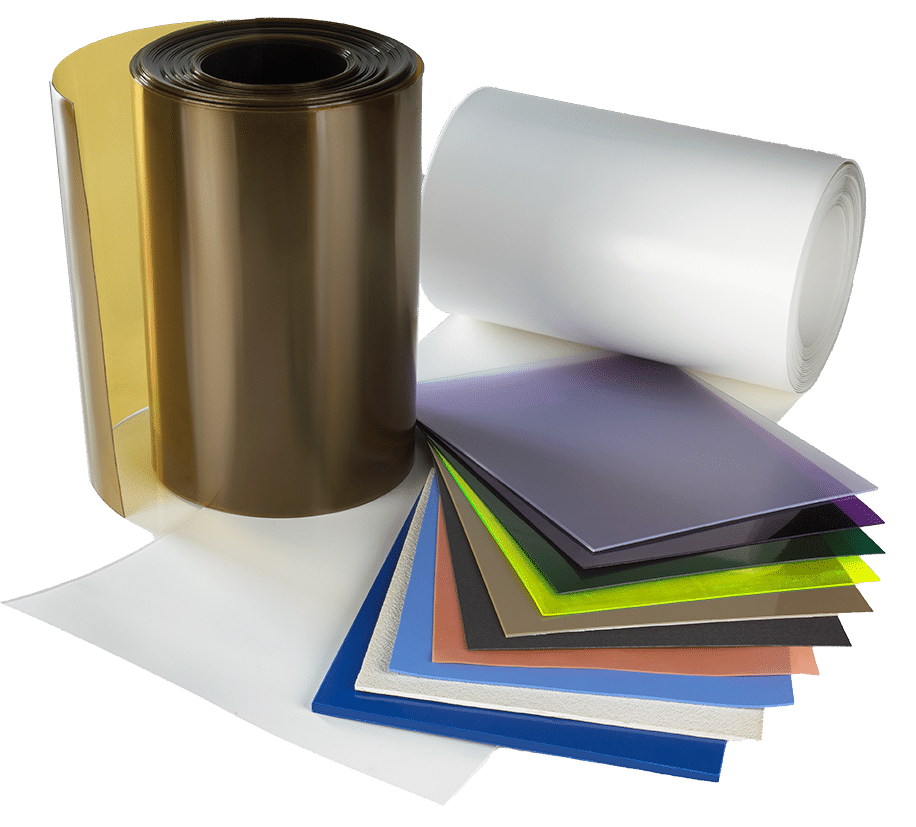

If you’re seeking thermoplastic sheet, there is no need to compromise with an off-the-shelf material or sheet size. We offer custom engineered sheet products that are far beyond what you’d expect from a typical sheet extrusion manufacturer!

Simply provide your material and sheet sizing requirements, and our Engineering Department will work with you to select an extrusion grade compound that is optimized for your product. We work in many different engineered resin systems and offer a wide range of thermoplastic technologies, including:

In addition to our thermoplastic technologies, we offer a wide range of extrusion options:

- Custom sheet sizing, including rolls

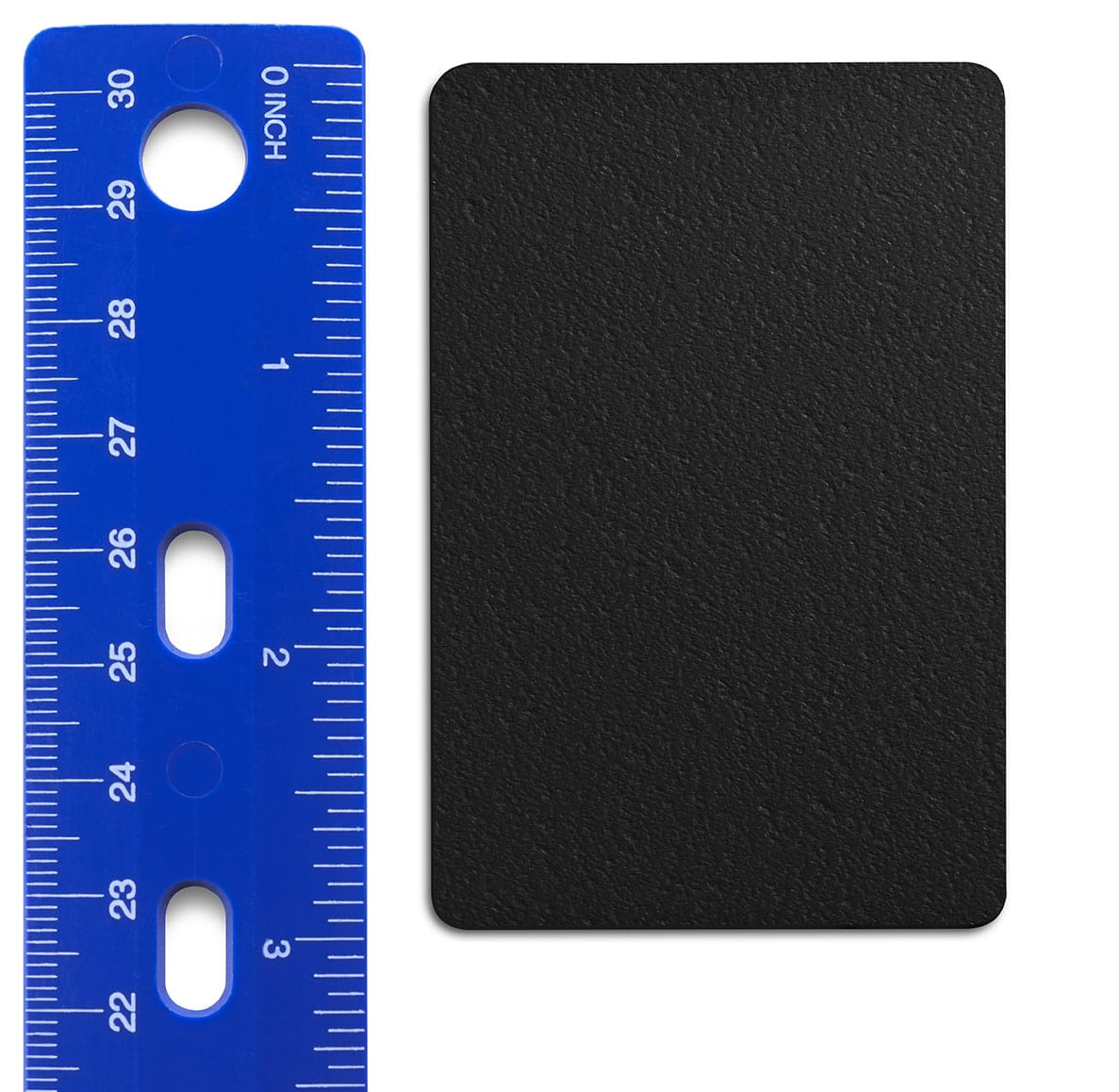

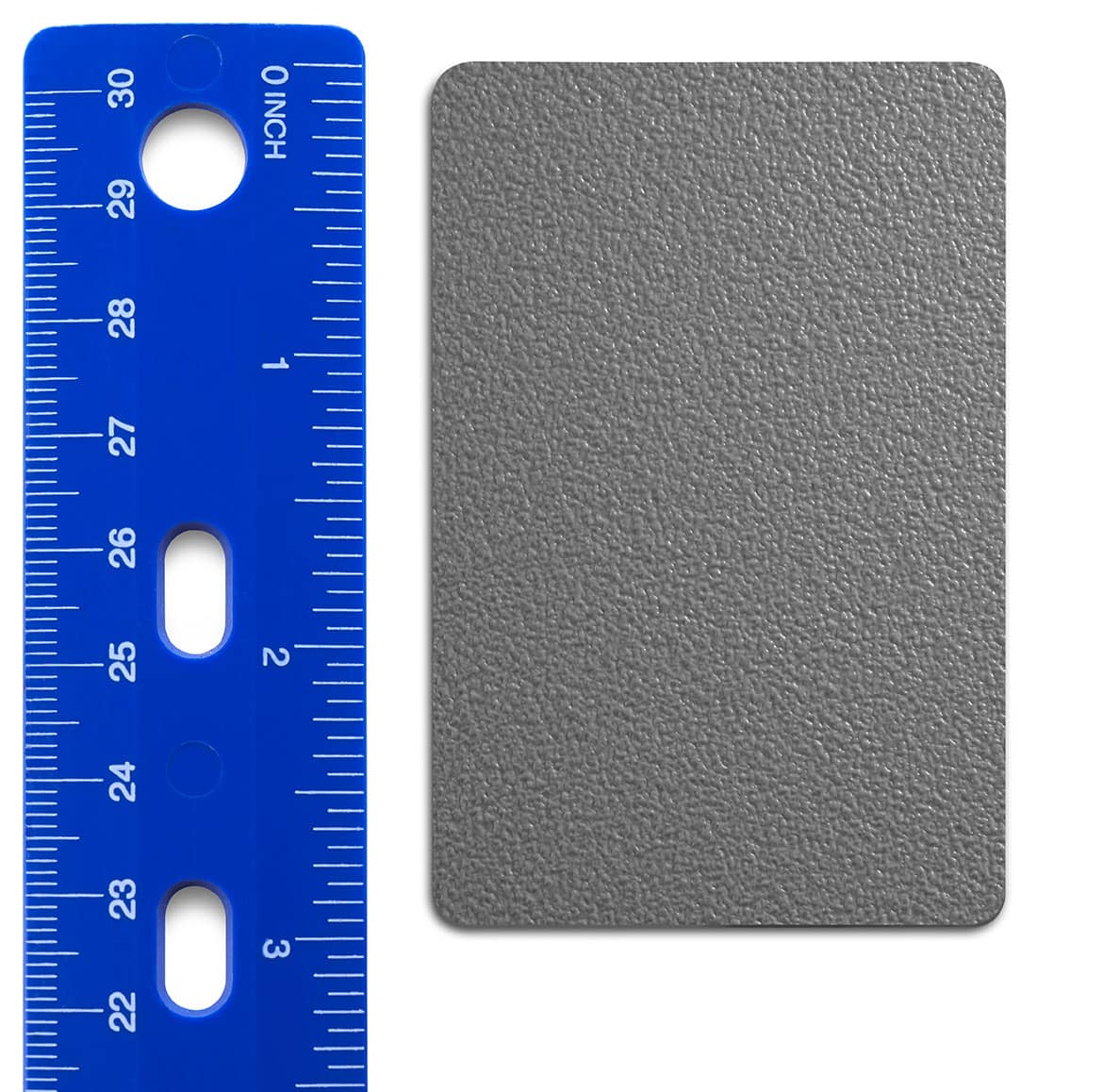

- Multiple different surface textures

- Protective masking

- Cap stock / film laminating

Available textures include: Smooth, Matte, Heavy Grain, and Haircell.

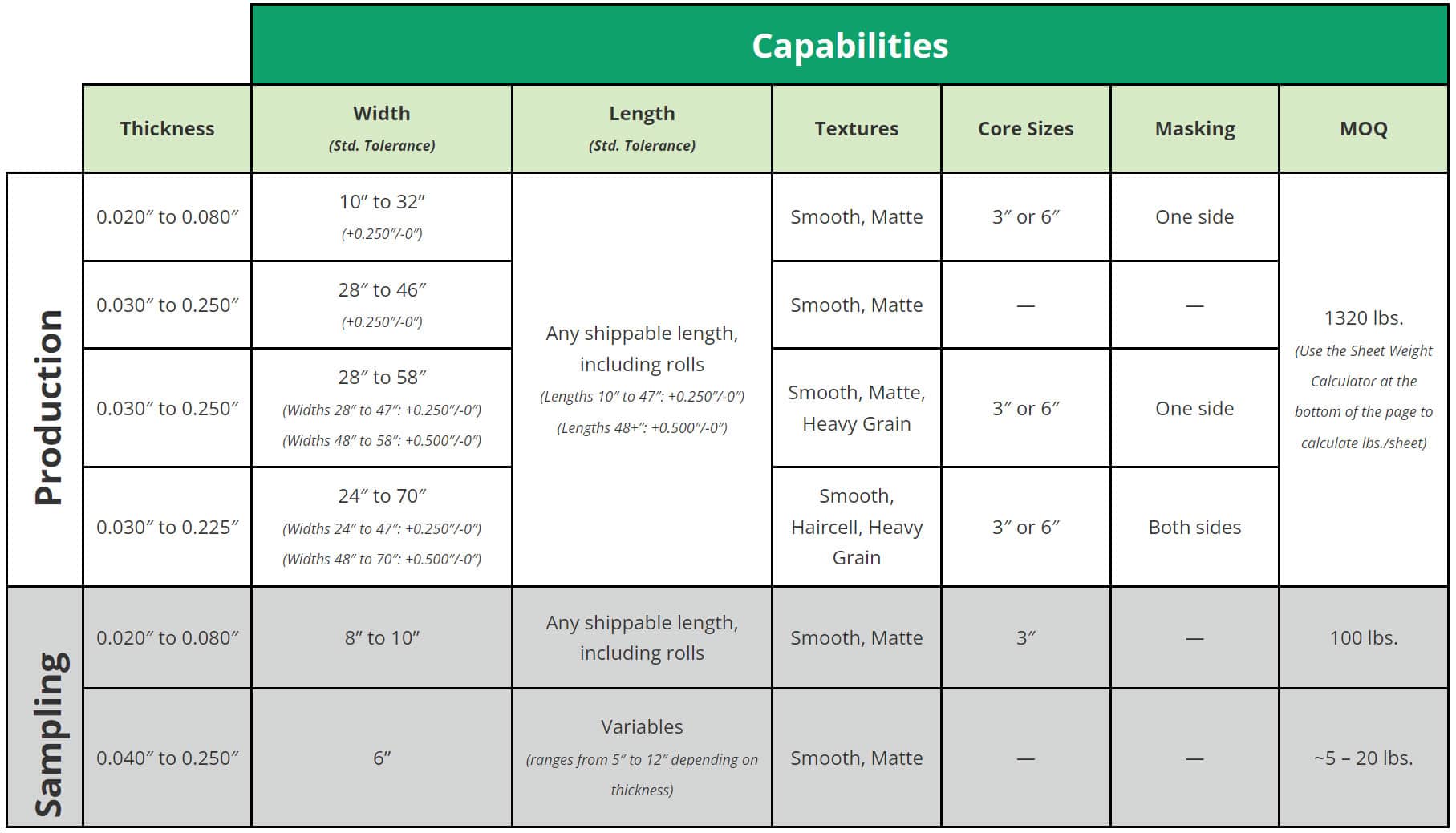

| Capabilities | ||||||||

| Thickness | Width (Std. Tolerance) |

Length (Std. Tolerance) |

Textures | Core Sizes | Masking | MOQ | ||

|

Production

|

0.020″ to 0.080″ | 10” to 32” (+0.250″/-0″) |

Any shippable length, including rolls (Lengths 10″ to 47″: +0.250″/-0″) (Lengths 48+”: +0.500″/-0″) |

Smooth, Matte | 3″ or 6″ | One side | 1320 lbs. (Use the Sheet Weight Calculator at the bottom of the page to calculate lbs./sheet) |

|

| 0.030″ to 0.250″ | 28″ to 46″ (+0.250″/-0″) |

Smooth, Matte | — | — | ||||

| 0.030″ to 0.250″ | 28″ to 58″ (Widths 28″ to 47″: +0.250″/-0″) (Widths 48″ to 58″: +0.500″/-0″) |

Smooth, Matte, Heavy Grain | 3″ or 6″ | One side | ||||

| 0.030″ to 0.225″ | 24″ to 70″ (Widths 24″ to 47″: +0.250″/-0″) (Widths 48″ to 70″: +0.500″/-0″) |

Smooth, Haircell, Heavy Grain | 3″ or 6″ | Both sides | ||||

|

Sampling

|

0.020″ to 0.080″ | 8” to 10” | Any shippable length, including rolls | Smooth, Matte | 3″ | — | 100 lbs. | |

| 0.040″ to 0.250″ | 6” | Variable (ranges from 5″ to 12″ depending on thickness) |

Smooth, Matte | — | — | ~5 – 20 lbs. | ||

Note: for rolls, substitute the length for 36 inches (one linear yard) to determine the pounds per linear yard