Search Case Studies

End-Use Case Study

- Compounding Technology Benefits Critical Sensor

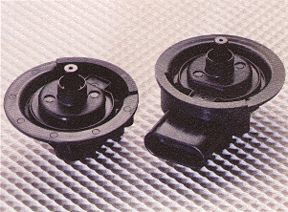

RTP Company and CTS Automotive Products, headquartered in Elkhart, IN, teamed-up to meet two sets of strict material performance requirements. The parts are the housing and the drive arm.

The sensors monitor the EGR valve position, enabling more accurate control of the EGR flow rate. The computer system then “adjusts” engine performance to assure acceptable emissions.

The CTS EGR sensor features an operating temperature range of -40 degrees F to 347 degrees F and is designed, tested and proven effective in extremely harsh conditions.

While EGR sensors are commonly associated with automotive applications, they are also suitable for use in industrial, agricultural and construction equipment. CTS is a world-leading supplier of vehicle sensors, specializing in electromechanical, electrical control and contacting/non-contacting sensor products.

The EGR sensor housing requires high thermal stability, wear resistance and strength requirements at elevated temperatures. A glass-reinforced RTP 1000 Series (PBT) specialty compound meets all requirements for the application. The PBT material exhibits 0.003 in./in. mold shrinkage at 1/8 in. and a heat deflection temperature of 415 degrees F at 264 psi. Equally important is the material’s un-notched impact strength of 11 ft. lbs./in at 1/8 in. and flexural strength of 27,000 psi.

The sensor’s drive arm is designed for minimum wear and high sensor accuracy, enabling consistent vehicle emission performance. This requires lubricity, strength and thermal stability. The RTP 1300 Series (PPS) glass-reinforced compound provides a dynamic coefficient of friction of 0.14 and an un-notched impact strength of 9 ft. lbs/in. at 1/8 in.