High temperature materials are divided into two main categories—semi-crystalline and amorphous—based on their difference in molecular structure.

Amorphous high temperature resins have a randomly ordered molecular structure which does not have a sharp melt point; instead amorphous materials soften gradually as the temperature rises.

These materials change viscosity when heated, but seldom are as easy flowing as semi-crystalline materials. They are isotropic in flow, shrinking uniformly in the direction of flow and transverse to flow. As a result, amorphous materials typically exhibit lower mold shrinkage and less tendency to warp than the semi-crystalline materials.

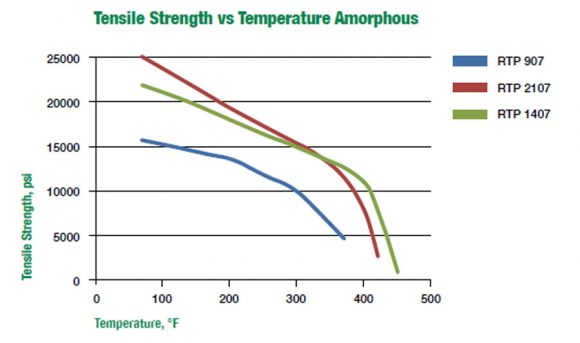

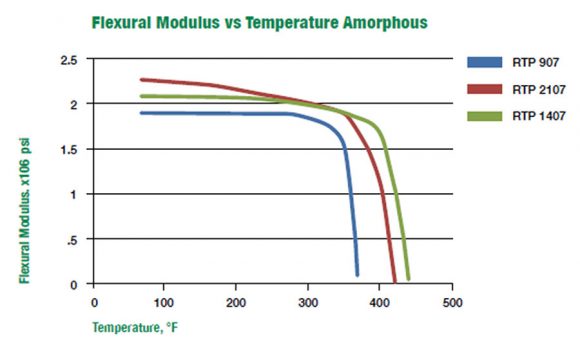

Amorphous resins lose their strength quickly above their glass transition temperature (Tg).

RTP Company modifies the following amorphous thermoplastic resins to meet the particular demands of your high temperature application:

| Product Data Sheets | Resin Description |

|---|---|

| RTP 900 Series | Polysulfone (PSU) |

| RTP 1400 Series | Polyethersulfone (PES) |

| RTP 2100 Series | Polyetherimide (PEI) |

Properties vs. Temperature for Amorphous, 40% Glass Fiber Filled Compounds

Note that the amorphous polymers have a moderate and steady loss of properties until they approach their Tg. Then they rapidly lose strength and stiffness and become incapable of carrying a load.