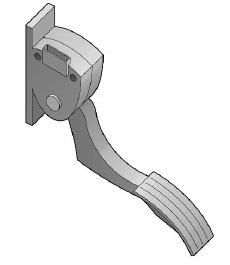

Application: Accelerator Friction Pad

Problem

Accelerator systems are now fully electronic “drive by wire”. The electronic housings need to be light weight and strong while the pedal needs to ‘feel’ like a mechanical system. (Heat range – 40°C to 80°C).

Solution

RTP 1300 Series PPS with glass fiber and PTFE

Benefits

- The wear compound was successfully developed with the right balance of friction and wear to provide the ‘feel’ required by the OEM.

- Light weight

- Excellent dimensional stability

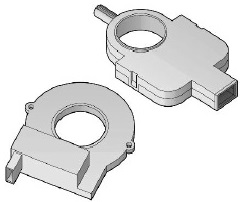

Application: Steering Position Sensor

Problem

There is a part of the steering position assembly where a shaft rotates inside the position sensor with tight tolerances which can lead to unwanted noise and wear.

Solution

RTP 4000 Series PPA with glass fiber and PTFE

Benefits

- Internal lubricants

- Reduced friction

- Reduced noise (squeaking)

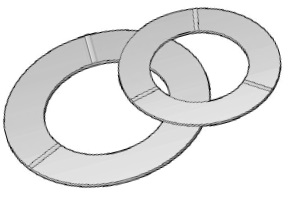

Application: Transmission Seals & Washers

Problem

Government regulation for fuel efficiency is driving the need for higher performance wear compounds in the power-train. The industry is also trying to increase efficiency & reduce weight to increase fuel economy. This application operates in transmission fluid with high PV.

Solution

RTP 2200 Series with Ultra Wear additives

Benefits

- Eliminates the need to machine a part from a stock form

- Significant reduction in manufacturing cost

- Reduced coefficient of friction

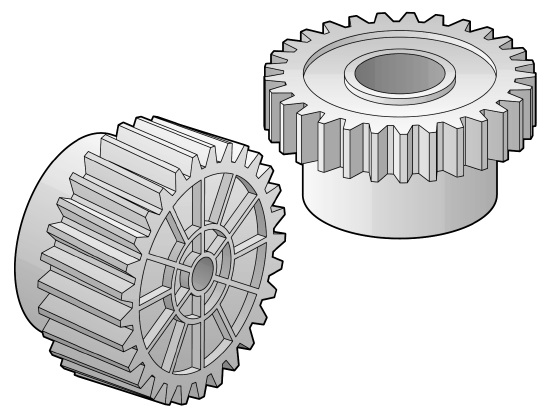

Application: HVAC Gears

Problem

Due to extreme temperature changes (-400c to 800c) gears were creating excessive noise leading to warranty issues.

Solution

RTP 200 series and 800 series with glass fiber and PTFE.

Benefits

- Noise reduction

- Low friction

- Improved wear resistance